What Plastic is Used in Extrusion?

In manufacturing, one process stands out for its versatility and widespread use - plastic extrusion. This technique, involving melting raw plastic and forming it into a continuous profile, is utilized across various industries, from automotive to construction.

The key to optimal plastic extrusion lies in the selection of the right kind of plastic - a seemingly simple decision that holds a significant impact on the end product's quality and performance.

E&C, a trailblazer in the realm of custom plastic extrusion, emphasizes the critical role that this choice plays in the process.

Choosing the correct plastic for extrusion can be the difference between a product that excels and one that disappoints. This guide aims to shed light on this crucial topic, providing insights to help you make an informed decision.

With E&C's wealth of knowledge and industry expertise, you're in good hands as we navigate the complexities of plastic extrusion together. Get a quote now.

Overview of Plastic Extrusion

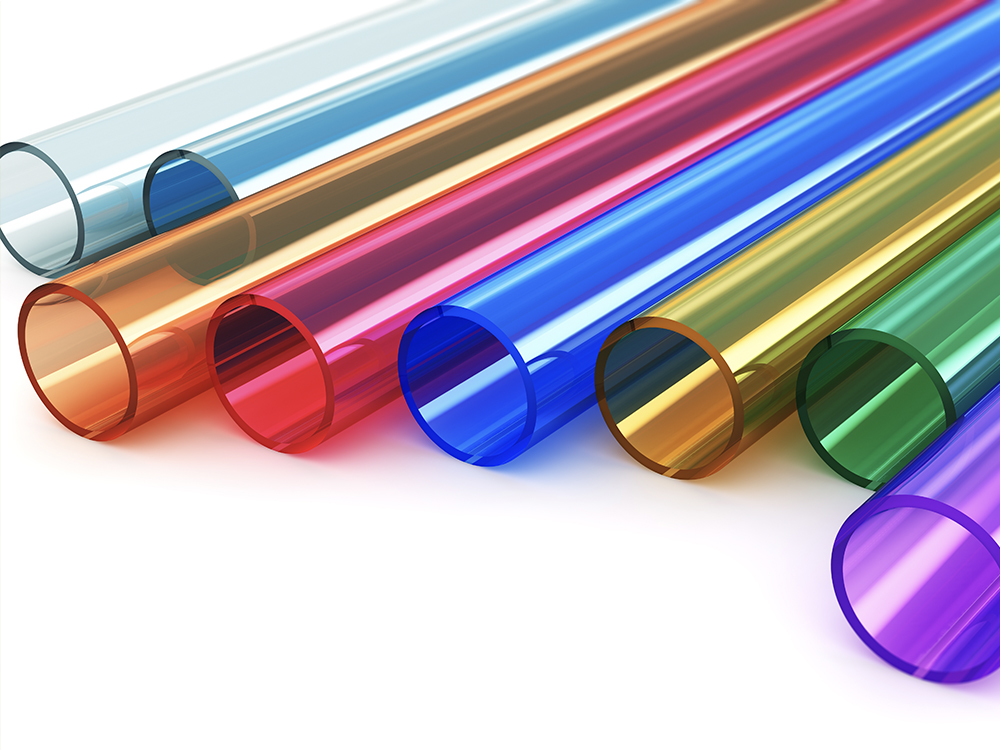

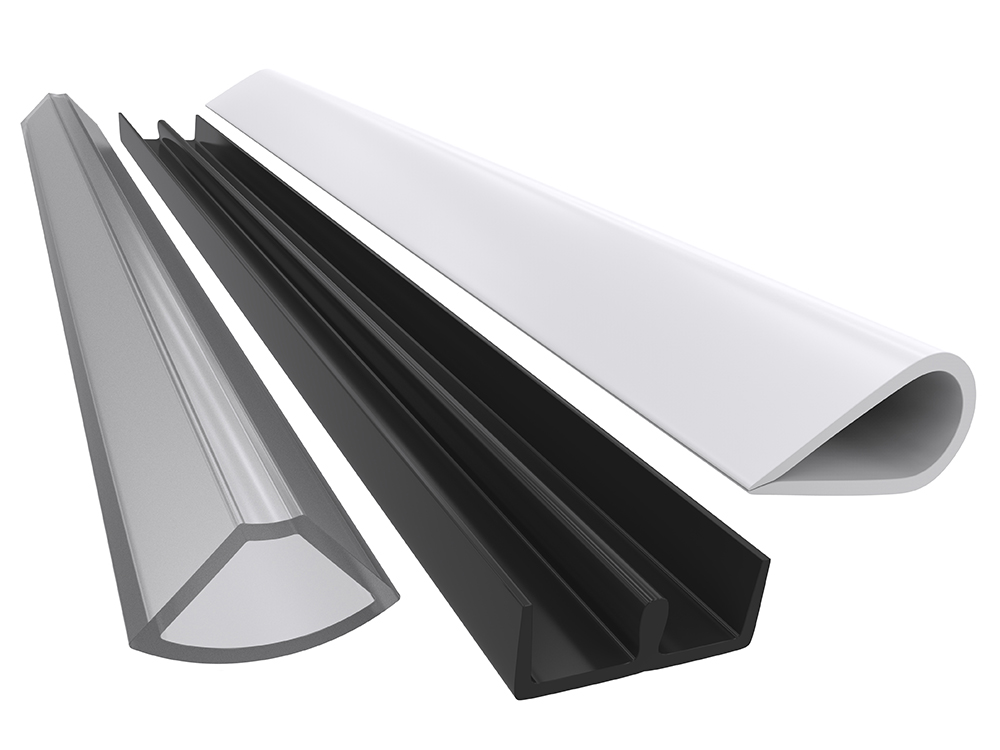

Plastic extrusion is a sophisticated manufacturing process that involves melting raw plastic and shaping it into a seamless, continuous profile. This high-volume technique allows for efficient production and consistent quality, making it a preferred choice in various industries. It's a method extensively used in the production of various items we use daily - from window frames and plastic films to tubing and pipes.

The versatility of this process lies in its adaptability to different types of plastics and numerous applications that span industries. Whether it's in the automotive sector for the creation of car parts or in the construction industry for the development of insulating materials, plastic extrusion has proven its utility time and again.

The Role of Material Choice in the Extrusion Process

The plastic type choice is not just a minor detail in the extrusion process; rather, it's a fundamental decision that significantly influences the quality and performance of the final product. Different plastics have varying properties such as melting point, strength, and flexibility, all impacting the extrusion process and end product features.

For instance, Polyvinyl Chloride (PVC) is a popular choice for its high durability and cost-effectiveness, making it ideal for construction materials. On the other hand, Polyethylene (PE), known for its flexibility and chemical resistance, is extensively used in the packaging industry.

Ultimately, understanding the properties of different plastics and aligning them with the intended application of the end product is crucial in the extrusion process. So, choosing plastic isn't just about what works but what works best for your specific needs and objectives.

What to Consider When Choosing a Plastic for Extrusion

When participating in an extrusion project, it's vital to consider certain factors that will significantly influence the success of your work. Selecting the right plastic isn't just about picking any material that fits the bill - it's about matching the properties of the plastic to your specific needs. Here's what you need to consider:

Durability

The lifespan of your end product is heavily dependent on the durability of the plastic used. Materials like Polyvinyl Chloride (PVC) are known for their robustness, making them excellent choices for long-lasting products, especially in the construction industry.

Flexibility

If your project requires the end product to bend without breaking or losing form, then flexibility is a key consideration. Polyethylene (PE), for instance, is highly flexible, which makes it a preferred choice for packaging materials.

Heat Resistance

The melting point of the plastic is crucial in the extrusion process, with different plastics responding differently to heat. Plastics with high heat resistance can withstand more demanding environments, which can be critical depending on the intended use of the end product.

Cost

While the best plastic for your needs may be obvious, the cost can be a determining factor. Some plastics, such as PVC, are durable and cost-effective, striking a balance between quality and economy.

Intended Application

Lastly, the intended application of the end product will guide your choice of plastic. Every plastic has unique properties; aligning these with your product's purpose will ensure you choose a plastic that suits your specific objectives.

Remember, each of these factors can significantly influence the success of your extrusion project. Choose wisely and purposefully to ensure the end product matches its intended quality and functionality.

Comparison of Popular Plastics Used in Extrusion

Here is a detailed comparison of the commonly used plastics in extrusion: Polyvinyl Chloride (PVC), High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), Polypropylene (PP), and Acrylonitrile Butadiene Styrene (ABS).

Polyvinyl Chloride (PVC)

PVC is well-known for its toughness and cost-effectiveness, making it a favorite in the construction industry. It is typically used for products that require high durability and low costs. However, when burned, PVC can release toxic fumes, posing potential environmental concerns.

High-Density Polyethylene (HDPE)

HDPE is highly resistant to impact, weather conditions, and certain chemicals, making it ideal for products intended for outdoor use, like playground equipment. The downside is that HDPE may degrade with prolonged UV exposure.

Low-Density Polyethylene (LDPE)

LDPE is prized for its flexibility and is widely used in the production of flexible tubes and plastic bags. It is also cost-effective. However, LDPE is not as durable or heat resistant as other plastics, limiting its use in products that withstand harsh conditions.

Polypropylene (PP)

PP has excellent resistance to heat and chemicals. It is commonly used in packaging, automotive applications, and household items. However, PP is not as flexible as PE and may become brittle with age and exposure to sunlight.

Acrylonitrile Butadiene Styrene (ABS)

ABS combines the strength of acrylonitrile and styrene polymers with the toughness of polybutadiene rubber. It is widely used in the production of Lego bricks and other toys due to its high durability. However, it is more expensive than other plastic types.

Remember, each plastic has its unique properties and trade-offs. Your choice should ideally be based on the specific requirements of your end product.

Best Plastics for Various Applications

From construction to packaging, the versatility of plastic materials is evident in their widespread use. Let's do a deep dive into which plastics are best suited for different applications.

Plastics in Construction

In the realm of construction, high-density polyethylene (HDPE) is the undisputed champion. Its resistance to impact and weather conditions makes it a go-to material for creating resilient infrastructure. HDPE can be used to construct an outdoor playground that will stand up to years of use and varying weather conditions.

Plastics in Packaging

When it comes to packaging, polypropylene (PP) and low-density polyethylene (LDPE) are often the materials of choice. LDPE is perfect for making lightweight, flexible packaging like cling films and plastic bags.

Meanwhile, PP's excellent heat resistance makes it ideal for microwave-safe packaging. We can produce a line of eco-friendly food packaging, with the flexibility of the material allowing for a range of product designs.

Plastics in Automotive

The automotive industry often leans towards acrylonitrile butadiene styrene (ABS) and PP due to their strength and heat resistance. ABS's exceptional durability renders it ideal for automotive components that must endure substantial wear and tear while maintaining optimal performance.

Similarly, PP's chemical resistance makes it ideal for components exposed to various automotive fluids. For instance, in a past E&C project, ABS was used to manufacture durable, long-lasting dashboard components.

The Role of Customization in Plastic Selection

At E&C, we understand that each project has its unique demands. That's why we offer a bespoke consultation service, helping our clients choose the perfect plastic based on their specific needs.

Whether you require high-impact resistance or superior heat tolerance, we utilize our vast knowledge and experience to guide you toward the optimal material. This approach is efficient and cost-effective, ensuring that you receive the highest quality solution within your budget.

The Power of Custom Extrusion Services

Our custom extrusion services provide an unparalleled advantage. With E&C, you're not confined to a one-size-fits-all approach. We tailor our strategies and materials to match your specific requirements, achieving an ideal balance between performance, aesthetics, and cost.

You gain access to a wider range of materials, finishes, sizes, and shapes through custom extrusion, allowing you to bring your vision to life in its most accurate form.

The Future of Plastic Extrusion: Innovative Materials

The world of plastic extrusion is consistently evolving, with innovative materials emerging to meet the industry's ever-changing needs.

Biodegradable plastics and composites are gaining traction for their eco-friendly properties and high-performance characteristics. These advancements stand poised to revolutionize future projects, pushing the boundaries of what's possible within the realm of plastic extrusion.

Your Project in Our Safe Hands

Selecting the right plastic for extrusion is crucial to the success of any project. Materials like HDPE, LDPE, PP, and ABS have demonstrated their diverse capabilities, from construction and packaging to automotive applications.

The future holds even more promise with the rise of innovative materials. At E&C, we are dedicated to helping our clients navigate this complex landscape through our customized consultation and extrusion services. Ready to start your next project with us? Contact us or request a quote today!